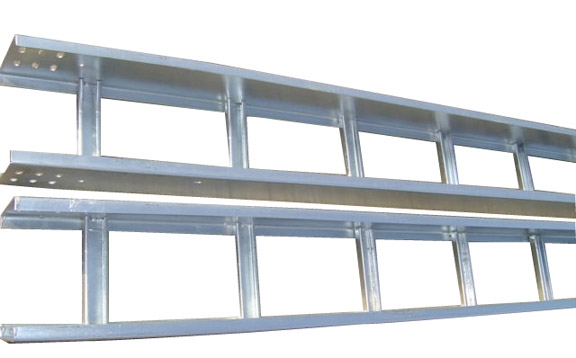

大跨距橋架安裝和布線(xiàn)注意事項

大跨距橋架具有運用壽命長(cháng)、設備便利且低成本、維護簡(jiǎn)練等優(yōu)越性。但大跨距橋架起備和布線(xiàn)是非常精密雜亂的事。以下是一些注意事項。

Long span bridge has the advantages of long service life, convenient equipment and low cost, simple maintenance and so on. But the preparation and wiring of long-span bridge is very precise and messy. Here are some considerations.

大跨距橋架作為布線(xiàn)工程的一個(gè)配套項目,現在尚無(wú)專(zhuān)門(mén)的規范閱歷,各生產(chǎn)廠(chǎng)家的規范程式短少通用性,因此,規劃選型進(jìn)程應依據弱電各個(gè)系統纜顯得類(lèi)型、數量,合理選定適用的橋架;如與大跨距橋架合用時(shí),應將電力電纜和弱電電纜各直一側,選用隔板分隔;大跨距電纜與其它低電壓電纜合用橋架時(shí),應嚴格執行挑選具有外屏蔽層的弱電系統的弱電電纜,避免相互間的攪擾??傊?在規劃、制作、設備、架起大跨距橋架時(shí),有必要依據運用環(huán)境,因地制宜擬定可行性方案,選用相應方法,提巨大跨距橋架質(zhì)量,以收到更好的效果。

As a supporting project of wiring engineering, there is no special specification experience for long-span cable tray, and the specification program of each manufacturer is short of generality. Therefore, the planning and selection process should reasonably select the suitable cable tray according to the type and quantity of each weak current system cable; If it is used with long-span bridge, the power cable and weak current cable should be separated on each straight side, and the center should be separated by partition; When long span cables and other low voltage cables share the same bridge, the selection of weak current cables with external shielding layer of weak current system shall be strictly implemented to avoid mutual interference. In a word, when planning, making, equipping and erecting large span bridge, it is necessary to draw up feasible scheme according to the application environment and local conditions, select corresponding methods, and improve the quality of large span bridge, so as to receive better effect.

大跨距橋架起備注意事項:

Precautions for large span bridge operation:

1、橋架高度:高度為50、100時(shí)每端各6只聯(lián)接孔,高度為150、200時(shí)每端各12只聯(lián)接孔。

1. Bridge height: when the height is 50 and 100, there are 6 connecting holes at each end, and when the height is 150 and 200, there are 12 connecting holes at each end.

2、支撐距離:支撐距離應小于等于載荷曲線(xiàn)容許載荷和支撐跨距。

2. Support distance: the support distance shall be less than or equal to the allowable load of load curve and support span.

3、橋架寬度:挑選電纜橋架的寬度時(shí),應留有必定的備用空位,以便為往后增加電纜用。

3. Bridge width: when selecting the width of the cable bridge, there should be a certain spare space for the future increase of cable.

4、離隔敷設:當電力電纜和控制電纜較少時(shí),可以在同一電纜橋架起備,但須用隔板將電力電纜和控制電纜離隔敷設。

4. Separated laying: when there are few power cables and control cables, they can be prepared in the same cable tray, but the power cables and control cables must be separated by a partition in the center.

5、電纜固定:匯線(xiàn)橋架水平敷設時(shí),橋架之間的聯(lián)接應盡量設置在跨距1/4處。水平走向的電纜每隔2米左右固定一下,筆直走向的電纜每隔1.5米左右固定一下。

5. Cable fixation: when the cable tray is laid horizontally, the connection between the cable trays should be set at 1 / 4 of the span as far as possible. The horizontal cable should be fixed every 2 meters or so, and the straight cable should be fixed every 1.5 meters or so.

大跨距橋架布線(xiàn)注意事項:

Precautions for large span cable tray wiring:

1、如果設備場(chǎng)所為具有腐蝕性或者是非常濕潤的環(huán)境,那么在布線(xiàn)時(shí)就有必要要依據腐蝕介質(zhì)的不同來(lái)選用相應的防護方法。

1. If the equipment site is corrosive or very humid environment, then it is necessary to choose the corresponding protection method according to the different corrosive medium when wiring.

2、若是將幾組電纜橋架一同在同一高度進(jìn)行平整設備的時(shí)分,就需要考慮各組電纜橋架之間的維護和檢修距離。

2. If several groups of cable trays are leveled at the same height, the maintenance and overhaul distance between each group of cable trays should be considered.

3、在大跨距電纜橋架上時(shí)可以進(jìn)行無(wú)距離敷設電纜的,電力電纜在橋架內的橫斷面填充率要在40%以下,而控制電纜則應小于橋架橫斷面積的一半。

3. If the cable can be laid without distance on the long span cable tray, the filling rate of the power cable in the cross section of the tray should be less than 40%, while the control cable should be less than half of the cross section area of the tray.

4、設備大跨距電纜橋架的時(shí)分不能設備在具有腐蝕性氣體管道以及熱力管道的上方,在腐蝕性液體管道的下方也不能直接設備電纜橋架,若是有必要如此的話(huà)則應做好防護和隔熱方法。

4. When the equipment has a long span cable tray, the equipment shall not be placed above the corrosive gas pipeline and thermal pipeline, or directly under the corrosive liquid pipeline. If necessary, the protection and heat insulation methods shall be taken.

大跨距橋架的設備布線(xiàn)是非常精密和雜亂的一項作業(yè),如果在設備布線(xiàn)進(jìn)程中呈現失誤就可能對往后的運用構成很大的問(wèn)題,所以締造大跨距橋架進(jìn)程中,必定要注意施工。

The equipment wiring of long-span bridge is a very precise and messy operation. If there are mistakes in the process of equipment wiring, it may pose a great safety problem for the future application. Therefore, in the process of creating long-span bridge, we must pay attention to the construction safety.