電纜橋架選定的五條注意事項

1.確定方向:根據建筑平面布置圖,結合空調管線(xiàn)和電氣管線(xiàn)等設置情況、方便維修,以及電纜路由的疏密來(lái)確定電纜橋架的佳路由。在室內,盡可能沿建筑物的墻、柱、梁及樓板架設,如許利用綜合管廊架設時(shí),則應在管道一側或上方平行架設,并考慮引下線(xiàn)和分支線(xiàn)盡量避免交叉,如無(wú)其它管架借用,則需自設立(支)柱。

1. Determine the direction: According to the layout of the building, combined with the setting of air-conditioning pipelines and gas pipelines, convenient maintenance, and the density of cable routing to determine the best route of cable bridge. In the interior, as far as possible along the walls, columns, beams and floor slabs of the building, when using the comprehensive pipeline gallery to erect, it should be parallel on one side or above the pipeline, and consider the lead line and branch line as far as possible to avoid crossing, if there is no other pipe rack to borrow, it is necessary to set up (support) pillars.

2.荷載計算:計算電纜橋架主干線(xiàn)縱斷面上單位長(cháng)度的電纜重量。

2. Load calculation: Calculate the weight of the cable per unit length on the longitudinal section of the main trunk line of the cable bridge.

3.確定橋架的寬度:根據布放電纜條數、電纜直徑及電纜的間距來(lái)確定電纜橋架的型號、規格,托臂的長(cháng)度,支柱的長(cháng)度、間距,橋架的寬度和層數。

3. Determine the width of the bridge: determine the type and specification of the cable bridge, the length of the bracket, the length and spacing of the pillars, the width and the number of layers of the bridge according to the number of discharge cables, cable diameter and cable spacing.

4.確定安裝方式:根據場(chǎng)所的設置條件確定橋架的固定方式,選擇懸吊式、直立式、側壁式或是混合式,連接件和緊固件一般是配套供應的,根據橋架結構選擇相應的蓋板。

4. Determine the installation mode: determine the fixing mode of the bridge frame according to the setting conditions of the place, choose suspension type, vertical type, side wall type or hybrid type, the connectors and fasteners are generally supplied with a complete set, and select the corresponding cover according to the structure of the bridge frame.

5.繪出電纜橋架平、剖面圖,局部部位還應繪出空間圖,開(kāi)列材料表。

5. Draw the plane and section of cable bridge, and the space map and material table should also be drawn in part.

電纜橋架的選擇要求

Selection Requirements of Cable Bridge Frame

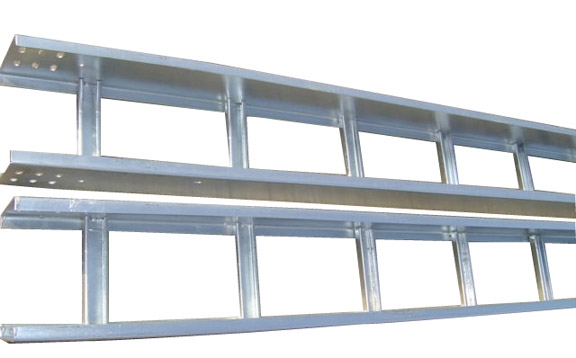

當鋼制直線(xiàn)段長(cháng)度超過(guò)30m,鋁合金電纜橋架超過(guò)15m時(shí).或當玻璃鋼電纜橋架經(jīng)過(guò)建筑伸縮(沉降)縫時(shí)應留有O-30mm補償余量.其連接宜采用伸縮連接板。

When the length of steel straight section exceeds 30m and the length of aluminium alloy cable tray exceeds 15m, or when the FRP cable tray passes through the expansion (settlement) joint of the building, the O-30mm compensation margin should be left. The expansion connection plate should be adopted.

電纜梯架、托盤(pán)寬度和高度的選擇應符合填充率的要求,玻璃鋼電纜橋架在梯架、托盤(pán)內的填充率一般情況下,動(dòng)力電纜可取40%-50%,控制電纜可取50%。70%.且宜預留l0%一252工程發(fā)展裕量。

The selection of cable ladder, tray width and height should meet the requirements of filling rate. Generally, the filling rate of FRP cable bridge in ladder and tray is 40% - 50% for power cable and 50% for control cable. 70%, and it is advisable to reserve l0% to 252 project development margin.

在選擇玻璃鋼電纜橋架的荷載等級時(shí),電纜橋架的工作均布荷載不應大于所選電纜橋架荷載等級的額定均布荷載,如果電纜橋架的支吊架的實(shí)際跨距不等于2m時(shí).則工作均布荷載應滿(mǎn)足:式中qG----工作均布荷載,kN/m;qE----額定均布荷載,kN/m;LG----實(shí)際跨距,m。

When choosing the load grade of FRP cable bridge, the working uniform load of the cable bridge should not be greater than the rated uniform load of the load grade of the selected cable bridge. If the actual span of the suspension of the cable bridge is not equal to 2 m, the working uniform load should meet the following requirements: middle qG - - working uniform load, kN/m; qE - - rated uniform load, kN/m; LG - - actual span, M.

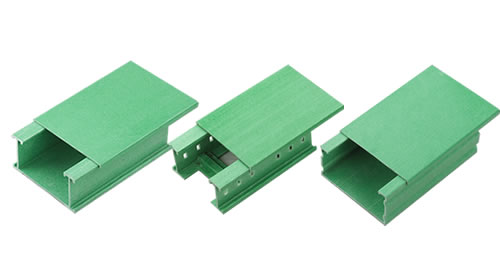

橋架的額定均布荷載等級需要屏蔽電磁干擾的電纜線(xiàn)路.或有防護外部影n向如戶(hù)外日照,油,腐蝕性液體、易燃粉塵等環(huán)境要求時(shí).應選用無(wú)孔托盤(pán)式玻璃鋼電纜橋架。

When the rated uniform load grade of the bridge needs to shield the cable lines from electromagnetic interference, or when there are environmental requirements such as outdoor sunshine, oil, corrosive liquids, flammable dust, etc. to protect the external shadow, the non-hole tray type FRP cable bridge should be selected.

在容易積聚粉塵的場(chǎng)所,玻璃鋼電纜橋架應選用蓋板;在公共通道或室外跨越道路段,底層橋架上宜加墊板或使用無(wú)孔托盤(pán)。

In places where dust is easy to accumulate, cover plate should be used for FRP cable tray; in public passage or outdoor crossing road section, pad plate or holeless tray should be added to bottom bridge tray.