電纜橋架水平敷設在設備距離的要求

在工程設計中,橋架的布置應根據經(jīng)濟合理性、技術(shù)可行性、運行性等因素綜合比較,以確定方案,還要充分滿(mǎn)足施工安裝、維護檢修及電纜敷設的要求。

In the engineering design, the layout of the bridge should be based on the comprehensive comparison of economic rationality, technical feasibility, operation safety and other factors to determine the scheme, but also fully meet the requirements of construction and installation, maintenance and cable laying.

橋架水平敷設時(shí)距地面的高度一般不低于于2.5m,垂直敷設時(shí)距地面1.8m以下部分應加金屬蓋板保護,但敷設在電氣專(zhuān)用房間內時(shí)除外。電纜橋架水平敷設在設備夾層或馬道且低于2.5m,應采取保護接地措施。

When the bridge is laid horizontally, the height from the ground is generally not less than 2.5m. When it is laid vertically, the part below 1.8m from the ground shall be protected by metal cover plate, except when it is laid in a special electrical room. If the cable tray is laid horizontally in the equipment mezzanine or catwalk and is less than 2.5m, protective grounding measures shall be taken.

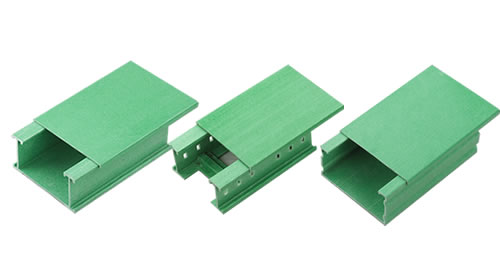

橋架、線(xiàn)槽及其支吊架使用在有腐蝕性環(huán)境中,應采用耐腐蝕的剛性材料制造?;虿扇》栏g處理,防腐蝕處理方式應滿(mǎn)足工程環(huán)境和耐久性的要求。對耐腐蝕性能要求較高或要求潔凈的場(chǎng)所,宜選用鋁合金電纜橋架。

Bridge, trunking and their supports and hangers shall be made of corrosion-resistant rigid materials when used in corrosive environment. Or adopt anti-corrosion treatment, which shall meet the requirements of engineering environment and durability. Aluminum alloy cable tray should be selected for places with high corrosion resistance or clean requirements.

橋架在有防火要求的區段內,可在電纜梯架,托盤(pán)內添加具有耐火或難燃性能的板,網(wǎng)等材料構成封閉或半封閉式結構,并采取在橋架及其支吊架表面涂刷防火涂層等措施。其整體耐火性能應滿(mǎn)足有關(guān)規范或標準的要求。在工程防火要求較高的場(chǎng)所不宜采用鋁合金電纜橋架。

In the section with fire protection requirements, the cable ladder and tray can be added with fire-resistant or flame-retardant board, net and other materials to form a closed or semi closed structure, and the fire-resistant coating shall be applied on the surface of the bridge and its supports and hangers. The overall fire resistance performance should meet the requirements of relevant national codes or standards. Aluminum alloy cable tray should not be used in places with high fire protection requirements.

電纜橋架作為布線(xiàn)工程的一個(gè)配套項目,尚無(wú)專(zhuān)門(mén)的規范指導,各生產(chǎn)廠(chǎng)家的規格形式缺乏通用性,因此,設計選型過(guò)程應根據電氣各個(gè)系統的電纜類(lèi)型、數量,合理選定適用的橋架。

As a supporting project of wiring engineering, there is no special specification guidance for cable tray, and the specification form of each manufacturer is lack of universality. Therefore, the design and selection process should reasonably select the suitable cable tray according to the type and quantity of cables in each electrical system.

(1)確定方向:根據建筑平面布置圖,結合空調管線(xiàn)和電氣管線(xiàn)等設置情況、方便維修,以及電纜路由的疏密來(lái)確定電纜橋架的路線(xiàn)。在室內,盡可能沿建筑物的墻、柱、梁及樓板架設,如需利用綜合管廊架設時(shí),則應在管道一側或上方平行架設,并考慮引下線(xiàn)和分支線(xiàn)盡量避免交叉,如無(wú)其它管架借用,則需自設立(支)柱。

(1) Determine the direction: according to the building layout plan, combined with the air conditioning pipeline and electrical pipeline setting, convenient maintenance, and cable routing density to determine the cable tray route. Indoors, it shall be erected along the wall, column, beam and floor of the building as far as possible. If it is necessary to use the comprehensive pipe gallery for erection, it shall be erected in parallel on one side or above the pipe, and the down lead and branch line shall be considered to avoid crossing as far as possible. If there is no other pipe rack to borrow, it is necessary to set up (support) column by itself.

(3)確定橋架的寬度:根據布放電纜條數、電纜直徑及電纜的間距來(lái)確定電纜橋架的型號、規格,托臂的長(cháng)度,支柱的長(cháng)度、間距,橋架的寬度和層數。

(3) Determine the width of cable tray: determine the model and specification of cable tray, the length of bracket, the length and spacing of pillar, the width and number of layers of cable tray according to the number of cables, cable diameter and cable spacing.

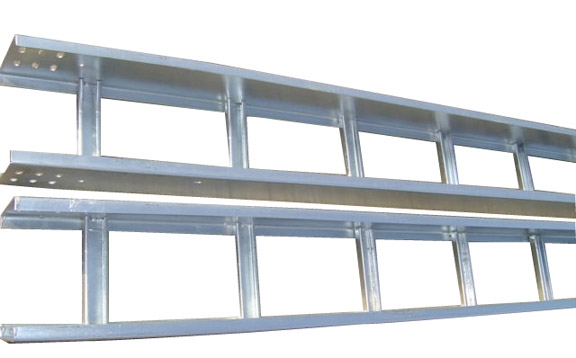

電纜橋架分為槽式、托盤(pán)式和梯架式、網(wǎng)格式等結構,由支架、托臂和安裝附件等組成。建筑物內橋架可以獨立架設,也可以敷設在各種建(構)筑物和管廊支架上,應體現結構簡(jiǎn)單,造型美觀(guān)、配置靈活和維修方便等特點(diǎn),全部零件均需進(jìn)行鍍鋅處理,安裝在建筑物外露天的橋架。

Cable tray is divided into trough type, tray type, ladder type and grid structure, which is composed of bracket, bracket and installation accessories. The bridge in the building can be erected independently or laid on various buildings (structures) and pipe gallery supports. It should reflect the characteristics of simple structure, beautiful appearance, flexible configuration and convenient maintenance. All parts should be galvanized and installed on the bridge outside the building.